Recycling and reusing

UU staff member Otto van de Beek makes sustainable tools for research and education

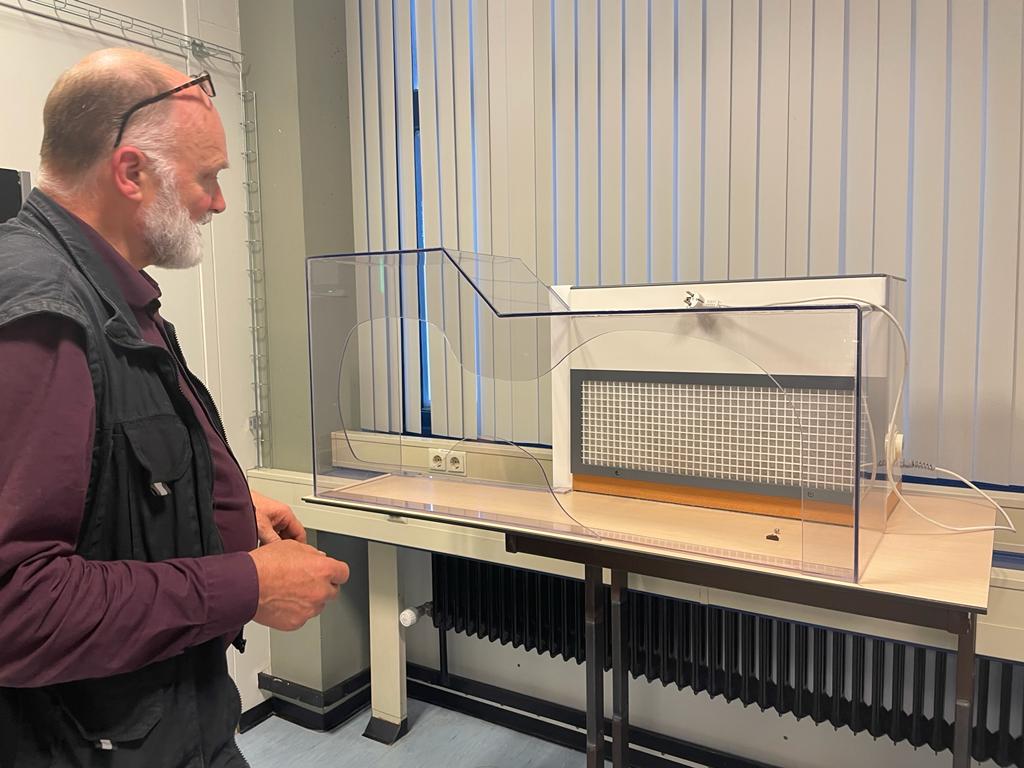

“I was asked to build an instrument on Tuesday”, van de Beek tells DUB as we're invited to take a closer look at his work. “I was able to deliver it in three days as I already had all the materials I needed. I collect all kinds of things that the university usually discards. If I had to order the materials first, we would have had to wait at least a month, which means the research would have been delayed too. It’s a win-win situation.”

Van de Beek (62) started his career at Utrecht University, working in the Faculty of Veterinary Medicine. “I worked there for over 20 years. I made a lot of instruments and learned a lot. I once developed a bolus, a sort of case for measurement instruments, which is put in a cow's stomach to measure its wellbeing. Thanks to the case, the instruments will last a lifetime. I love it when innovation contributes to a better world”.

After that, Van de Beek worked at the Facilities Service Center and at Real Estate & Campus. For the last eight years, he has been working at the Faculty of Science, where he currently serves as a precision mechanic and a coordinator for Jobshop, a workshop where Computer Science students have their practical exercises. There, the students learn how to make hardware and other instruments under Van de Beek's supervision. “I've got the best job I could dream of. Last year, I worked a lot of overtime — I would have never done that if I didn’t love my job.”

Jobshop, the workshop, is located in the Caroline Bleeker building

Van de Beek develops and manufactures equipment, always trying to reuse materials. “I have saved 250,000 euros over the past four years, just by reusing residual materials. When things get thrown away, it’s always been my approach to first see what can be salvaged. Every time I make something, I look at what I can reuse as that saves both money and time".

Recently, Van de Beek walked through the old Geosciences building, collecting a lot of materials like reducer valves, which he was able to use that same week. Since he has been working at Utrecht University for several years, he has built quite an extensive network, from which he profits daily. “I know what my colleagues are working on and what they need, so I can act quickly and bring research groups together. If a certain group needs a specific instrument, I get them to meet with another group using similar equipment, in order to foster collaboration. If a certain type of instrument is no longer being used – such as an ultracentrifuge I've recently learned about – I communicate that to another group that needs it. It can be that simple. People also know where to find me. Colleagues often send me messages with photos of objects, asking me whether I can find a purpose for them. Table frames, pressure gauges, written-off equipment... Mostly, it is possible to repurpose it, sometimes even that same day. At other times, it takes a little longer to find a new use for something, but it does get used eventually.”

An instrument with repurposed pressure gauges.

An instrument with repurposed pressure gauges.

Van de Beek’s workshop is located in the Caroline Bleeker building, on Sorbonnelaan Avenue, but his materials and instruments can be found in several different buildings in the Utrecht Science Park. Much of what Van de Beek builds is in the Kruyt building. Van de Beek gives us a tour of the building, pointing to what he has made. A table with frames that have been welded together made for carrying an exceptionally heavy machine; a customised cupboard that allows one to work with dangerous substances thanks to a built-in Hepa-filter. “The filter in this cupboard came from a machine I saved from the landfill.”

Customised cabinet with a built-in Hepa-filter

Customised cabinet with a built-in Hepa-filter

In the Kruyt building, we meet his colleague Arjan Hasselman, who leads the logistics team in the Facilities Service Centre. He has some material he thinks can be repurposed, so he is here to collect Van de Beek. Hasselman: “So much valuable material gets thrown out even though it can be repurposed. You just have to know where it can be used, and for what purpose. Van de Beek knows that, but we could easily fill a full-time position with this type of work.” Van de Beek adds: “We really need a system in which residual material or old equipment can be registered. I can intercept and repurpose a lot, but sometimes I worry about how things will go when I retire.” On the hunt for reusable materials

On the hunt for reusable materials